October 12, 2017

Our CB series aquaculture buoys have become the standard in Canada among the major aquaculture companies. When we were developing our buoys, we saw an opportunity to improve the durability, mechanical strength, & longevity of the buoys that were widely in use. Some key improvements that set apart our product are:

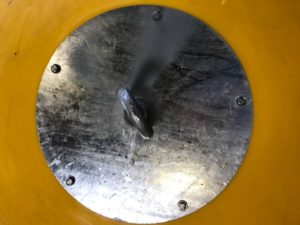

From our research, we found that the most common failure point of our competition’s buoys was a result of unsecured load plates. Over time, the through rods were being dislodged from the buoys necessitating frequent replacements.

We found that other company’s buoys were being pigmented with dry blending resulting in a weaker outer shell that is more prone to being compromised.

We have found many of our competitors’ flotation products to have poor EPS fusion which results in loose beads and voids allowing for significant water ingress. Some companies use polyurethane foam in place of EPS. Polyurethane is non-recyclable and it can produce significant voids inside the part. For these reasons as well as other factors, we choose to use EPS.

Our compensation buoys are also deployed for industrial mooring buoys for applications such as barrier booms and mooring of barges & ships. We recently supplied the US Department of Transportation with our CB1200 Standard buoys to be used as mooring buoys at the James River Reserve Fleet in Virginia. To learn more about our CB series click here.